Fire Protection Specialists

With over 135 years of experience, Wormald is the specialist in fire safety in Australia.

Fire Protection Specialists

With over 130 years of experience, Wormald is the specialist in fire safety in Australia.

Foam Fire Suppression Systems

Designing a foam fire suppression system requires special expertise – expertise that Wormald has developed over many years.

Wormald systems are reliable and suppresses the fire quickly, giving you confidence that fire risks are reduced to acceptable levels. For foam systems, foam must be delivered to the fire efficiently and in a controlled and directed manner. Our fire protection design engineers have experience over a vast range of installations and will analyse your facility, the fire risk and consider likely scenarios. They will design a system configuration to effectively combat fire, help you consider the options and decide upon the most suitable solution.

Low Expansion Foam

Low Expansion foam offers a 5:1 expansion rate, making it the foam system of choice in Australia to protect large and hazardous facilities, including; petro-chemical tank farms, loading docks, processing areas and refineries and liquefied natural gas storage.

Organisations storing or handling flammable and combustible liquids will usually need to comply with Australian Standards AS1940 ‘The Storage and Handling of Flammable and Combustible Liquids’ and Wormald can provide the design expertise and system components to help any facility comply with this Standard.

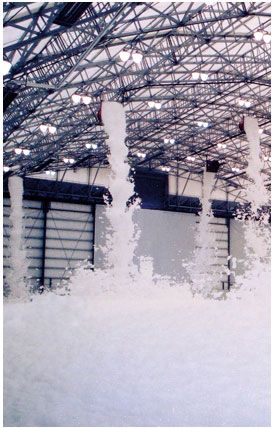

High Expansion Foam

With an expansion rate of 500:1, High Expansion foam systems are more suitable to protect less common three-dimensional hazardous facilities including; warehouses, conveyors, aircraft hangars and tunnels. As such, High Expansion foam is measured by volume output rather than application rate, as is typical of low expansion foams.

Discharge Devices

With both low and high expansion foam systems, once a facility has been evaluated either an ‘Aspirating’ or ‘Non-Aspirating’ discharge device’ will be recommended, based on the facilities requirements.

- Aspirating discharge devices – produces a more viscous foam – great for reducing burn back and keeping the foam contained.

- Non-aspirating discharge devices – are best used where the foam is needed to spread over a large area. Talk to a Wormald specialist about your situation.

For maximum effectiveness it is critical the expansion ratio, discharge device and foam concentrate be correct. With our knowledge and expertise, Wormald can recommend the most appropriate devices for your situation.

Wormald’s proactive stance on limiting firefighting foam contamination

Since the 1970s, Aqueous Film Forming Foams (AFFFs) have been used around the world to rapidly supress and extinguish fires. AFFFs are water-based firefighting foam products used to suppress flammable liquid fires by cooling the fire and coating the fuel, preventing its contact with oxygen.

However, in recent years AFFFs containing fluorine have been identified as having adverse impacts on the environment. Historically, many of these foams include fluorinated surfactants such as PFOA and PFOS, which are part of a broader group of chemicals called PFAS substances.

Queensland and South Australia are leading the way by banning or restricting firefighting foam products that contain PFAS, and as a signatory to the Stockholm Convention for the reduction of Persistent Organic Pollutants, the rest of the country is expected to follow suit.

Wormald has eliminated PFAS from its fire suppression products and has been working with Queensland and South Australian businesses to replace and dispose of AFFF firefighting foams.

Wormald’s exclusive partnership with 3F ensures a sustainable future using firefighting foams. 3F designs and manufactures high performance firefighting foams that minimise the environmental impact of firefighting in all sectors including, petrochemical, general chemical, waste, aviation, fire and emergency services, shipping, fixed fire suppression systems and portable fire extinguishers.

3F’s FREEDOL SF is a fluorine free and solvent free foam agent available locally via Wormald Australia. As a fluorine free product, FREEDOL SF is free of the persistent, toxic and bio-accumulative PFAS chemicals. Being free of solvents has the added environmental benefit of a significantly lower Chemical Oxygen Demand (COD) compared to other fluorine free foams and AFFFs. For example, a standard 6 per cent AFFF has a COD of 400 g/l. FREEDOL SF has a COD of 100 g/l. The lower COD results in less environmental impact as less oxygen is consumed while the product biodegrades.

Existing AFFF systems, either pre-engineered vehicle systems or fixed suppression systems, can be easily upgraded to use Fluorine Free and Solvent Free Foam from 3F. Minor modifications required include changes to proportioners or an increase in vehicle system cylinder pressure. Wormald has the expertise and experience to advise what system and product changes are required to convert to a more environmentally sensitive foam system without compromising fire protection performance.

Wormald Direct provides easy, instant access

to data relating to Service Calls and Test Results

Learn More

Fire Suppression Enquiry